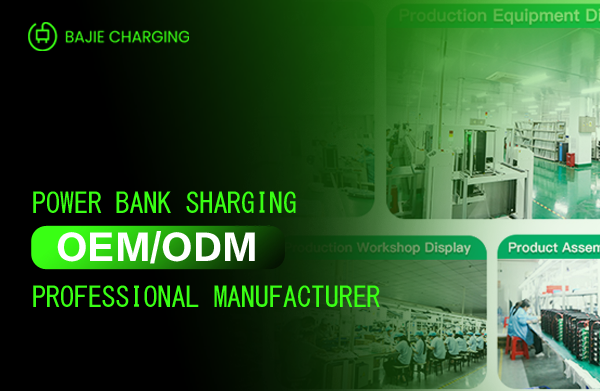

Equipped with a complete hardware supply chain, ranging from battery cell production to SMT chip mounting, plastic injection molding, wire production, and finished product assembly, as well as independently developed Internet of Things-based intelligent backend systems.

Products undergo a series of specialized tests, including electrical performance, environmental performance, safety performance, mechanical performance, high voltage/static electricity performance, and corrosion resistance, ensuring high-quality assurance in accordance with international standards and requirements such as lithium battery UN38.3.

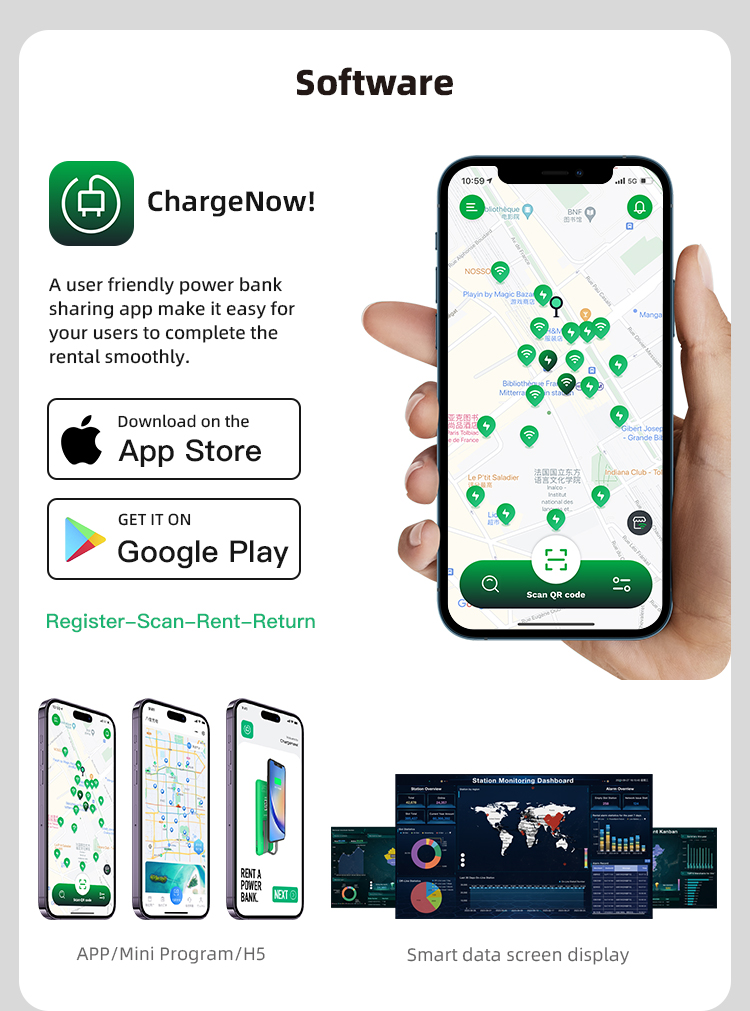

Given the heavy reliance of shared power bank projects on hardware devices, the software must be sufficiently intelligent. Deployed across hundreds of cities nationwide and even internationally, spanning tens of thousands or even millions of devices, effective daily operation, and management are essential.

Bajie Charging achieves efficient operation and management of large-scale equipment through “automatic system alarms,” enabling real-time monitoring of device conditions and proactive resolution of anomalies, thereby operating large-scale businesses cost-effectively.

Real-time device perception alarms provide 24/7 comprehensive monitoring of each device’s status and fault warnings, maintaining full lifecycle management from deployment to retirement, conducting health analysis on devices, and automating device maintenance.

After Bajie Charging’s products enter the market, they exhibit low incident rates and minimal corresponding customer complaint rates, significantly reducing market operation costs for global customers.