Raw Material Preparation:

The production of shared power banks requires various raw materials, including batteries, PCB boards, casings, wiring, etc. Among these, the battery is the core component, and choosing a high-quality battery is crucial. Our power banks use high-quality Tesla-sourced pure ternary lithium batteries to ensure safety and stability.

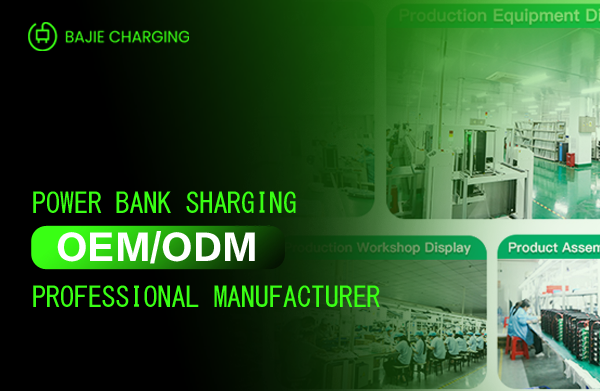

Production Processing:

After preparing the raw materials, assemble the casings with branded logos, batteries, PCB boards, etc., and perform wiring and soldering to produce the power banks and shared charging cabinets.

Quality Inspection:

Throughout the production of power banks, strict quality control is implemented at every step. Bajie Charging has established a comprehensive management system to ensure the stability and reliability of its products through scientific management and rigorous quality control.

After production, the factory conducts multiple quality inspections, including battery charging and discharging tests, internal structure checks of power banks, etc. Only products that meet all inspection standards can be sold.

Bajie Charging’s products have obtained international certifications such as BSMI, CB, PSE, UN38.3, etc. The charging cables are also Apple MFI certified, making Bajie Charging the exclusive MFI certification solution provider in the shared power bank industry.

Bajie Charging can provide customers with complete shared power bank solutions: customized software development, circuit design, and cabinet structure design based on customer needs.